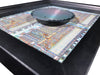

Silicon Wafer with 6502 Microprocessor Chips - 4 inch, Rockwell, MOS

ChipScapes

About this Artwork:

This silicon wafer was fabricated by Rockwell International in the mid-1980s. This wafer contains the Rockwell version of the MOS 6502 microprocessor. The wafer has about 410 microprocessors on it. Adjusted for inflation, the price per chip would be about $80, giving the wafer a value of about $32,800. After Motorola introduced the 6800, some of Motorola’s designers left to start MOS Technologies. Introduced in 1975, the 6502 processor was MOS’s first successful product. Although influenced by the design philosophy of the 6800, the 6502 is clearly a different and more advanced chip design. More important to its success though, the 6502 was designed as part of a whole family of 6500 series processors. The 6502 was the heart of several early microcomputers and game systems. Commodore, Apple, and Atari were among the 6502 designs. Apple designer, Steve Wozniak, described it as the first chip you could get for less than a hundred dollars (a quarter of the 6800 price). It became the microprocessor of choice for many hobbyists. Rockwell licensed the 6502 from MOS and became the second source of choice for the 6502. Soon Rockwell began producing other 6502 and 6800 components. As Rockwell’s experience increased, they began creating original variations that MOS did not make, such as the R6500 and R6511. Rockwell produced 6502 microprocessors longer than any other company.

About Making Computer Chips:

Computer chips start as ordinary sand, which is silicon dioxide. The first step is to melt the sand in a furnace that reaches about 3200 degrees F. The silicon is purified to create 99.9999% pure silicon. The silicon is broken up into chunks and melted in a crucible. A silicon crystal seed is dipped in molten silicon and slowly drawn out to create a cylinder of silicon. These silicon cylinders are some of the purest crystals on the planet. Once the silicon cylinder is grown to the desired diameter, it is sawed into wafers and polished to achieve a very flat mirror surface. Transistors, and other microelectronic parts, are built on the polished wafer in layers in a process called etching. The wafer is then sawed/diced into its individual chips. Each chip is mounted in an electronic package that protects it and connects it to the outside world. We essentially take a pile of sand and change it into thousands of dollars worth of computer chips.

Framing:

The artwork is framed in an 8"x10" black shadow box frame, with glass. All framing materials are acid-free. A narrative about the artwork that includes the artist’s signature is placed on the back of the artwork.

Please note: The look of the artifacts in the artworks may vary, each piece is unique.