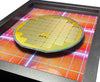

Field Programmable Gate Array - FPGA Silicon Wafer, 6", 150mm

About FPGAs

The acronym FPGA stands for Field Programmable Gate Array. It is an integrated circuit that can be programmed by a user for a specific use in the comfort of their own home or office. FPGAs consist of logical modules connected by routing channels. Each module is made up of a programmable lookup table used to control the elements that each cell consists of and perform logical functions of the elements that make up the cell. The photo to the right is a single cell of the FPGA chip on this silicon wafer.

About Silicon Wafer

This six-inch silicon wafer was made by GateField Corp in 1997. The wafer has 43 large, 14mm x 18mm, chips on it. These are ProASIC GF260F FPGA chips. Each chip had over 300,000 gate array equivalents. Each chip had non-volatile flash technology to retain programming during power cycles. These chips sold for about $600 in today's dollars. At 43 total chips on the wafer, this wafer would have a $25,000 value (given 100% yield). Most people might not recognize the name GateField. It is because GateField was acquired by Actel (2000), who was acquired by Microsemi (2010), who was acquired by Microchip Technology (2018). Many of the 20th-century semiconductor companies were swallowed by their competitors or other larger semiconductor companies that wanted to expand into new technology areas.

About Making Computer Chips

Computer chips start as ordinary sand, which is silicon dioxide. The first step is to melt the sand in a furnace that reaches about 3200o F. The silicon is purified to create 99.9999% pure silicon. The silicon is broken up into chunks and melted in a crucible. A silicon crystal seed is dipped in molten silicon and slowly drawn out to create a silicon cylinder. These silicon cylinders are some of the purest crystals on the planet. Once the silicon cylinder is grown to the desired diameter, it is sawed into wafers and polished to achieve a very flat mirror surface. Transistors, and other microelectronic parts, are built on the polished wafer in layers in an etching process. The wafer is then sawed/diced into its individual chips. Each chip is mounted in an electronic package that protects it and connects it to the outside world. We essentially take a pile of sand and change it into thousands of dollars worth of computer chips.

About ChipScapes

ChipScapeTM artworks are pictures taken of computer chips, sort of microscopic chip landscapes, or ChipScapes for short. This artwork was created by photographing computer chips on this silicon wafer using a microscope and special lighting.

Framing:

The artwork is framed in an 8"x10" black shadow box frame, with glass. All framing materials are acid-free. A narrative about the artwork that includes the artist’s signature is placed on the back of the artwork.

Please note: The look of the artifacts in the artworks may vary, each piece is unique.