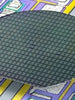

Rare 1960s 1.6" Silicon Wafer - Mullard FCH211 NAND/NOR Sextuple Inverter - 39mm

ChipScapes

About this Artwork:

Logic chips were the first computer chips. The Mullard FCH211 logic chip was produced in the mid-1960s. The FCH211 was a NAND/NOR Sextuple Inverter Gate. The name is a mouthful, and it was a very advanced and flexible chip, providing three logic functions for 6 inputs and outputs. There are about 480 DTL Mullard FCH211 logic chips on this silicon wafer. The artwork on the front shows individual chips on the wafer. The FCH211 had 6 transistors, 15 diodes, and 6 resistors on each chip.

The logic diagram to the right (on back of artwork) shows the circuit for the FCH211 logic chip. It is interesting to compare this logic diagram with the actual physical chip implementation on the front of the artwork. The input and output connections are identified on both the physical chip and the logic diagram.

Unless you are versed on chip design, you might not be able to recognize the diodes, transistors, and resistors in the FCH211 chip image on the front of the artwork. The images below (on back of artwork) provide a quick legend for identifying them. On the left is a diode that allows electricity to flow in one direction. In the middle is a transistor which is an electrically controlled switch. And to the furthest right is a resistor that impedes electrical flow (in the picture the resistor is vertical, however an unrelated trace is passing over it in the center going left to right).

About Making Computer Chips:

Computer chips start as ordinary sand, which is silicon dioxide. The first step is to melt the sand in a furnace that reaches about 3200o F. The silicon is purified to create 99.9999% pure silicon. The silicon is broken up into chunks and melted in a crucible. A silicon crystal seed is dipped in molten silicon and slowly drawn out to create a silicon cylinder. These silicon cylinders are some of the purest crystals on the planet. Once the silicon cylinder is grown to the desired diameter, it is sawed into wafers and polished to achieve a very flat mirror surface. Transistors, and other microelectronic parts, are built on the polished wafer in layers in an etching process. The wafer is then sawed/diced into its individual chips. Each chip is mounted in an electronic package that protects it and connects it to the outside world. We essentially take a pile of sand and change it into thousands of dollars worth of computer chips.

Framing:

The artwork is framed in an 8"x10" black shadow box frame, with glass. All framing materials are acid-free. A narrative about the artwork that includes the artist’s signature is placed on the back of the artwork.

Please note: The look of the artifacts in the artworks may vary, each piece is unique.