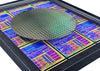

Silicon Wafer with Cellular Phone Chips - 8 inch,200mm, Broadcom

ChipScapes

About this Artwork:

Imagine holding a slice of the future in your palm, a circular canvas about 8 inches across, dotted with 440 sparkling technological gems. This isn't just any piece of tech; it's a silicon wafer, the birthplace of computer chips that powered the early 2000s' iconic GSM flip phones. Each chip is a marvel of miniature engineering, humming with the potential to process information, store memories, and connect voices across the globe.

The vibrant mosaics you see — the blues, greens, and reds — are not just for show. They are the logic grids and memory banks, the cradle of the phone’s intellect. The heart of these chips is a RISC microprocessor, a brain designed to execute commands efficiently and swiftly, partnered with a Digital Signal Processor, the artist translating electronic pulses into voices and images.

Crafted by Broadcom in the year 2000, these chips are a testament to the era's ingenuity, a time when the world was on the brink of a wireless revolution, and a flip phone was the epitome of cutting-edge technology. Each wafer represents a congregation of 440 possibilities, 440 pathways to connect, and 440 stepping stones into the age of mobile communication.

About Making Computer Chips:

Computer chips start as ordinary sand, which is silicon dioxide. The first step is to melt the sand in a furnace that reaches about 3200o F. The silicon is purified to create 99.9999% pure silicon. The silicon is broken up into chunks and melted in a crucible. A silicon crystal seed is dipped in molten silicon and slowly drawn out to create a cylinder of silicon. These silicon cylinders are some of the purest crystals on the planet. Once the silicon cylinder is grown to the desired diameter, it is sawed into wafers and polished to achieve a very flat mirror surface. Transistors, and other microelectronic parts, are built on the polished wafer in layers in a process called etching. The wafer is then sawed/diced into its individual chips. Each chip is mounted in an electronic package that protects it and connects it to the outside world. We essentially take a pile of sand and change it into thousands of dollars worth of computer chips.

Framing:

The artwork is framed in an 11"x14" black shadow box frame, with glass. All framing materials are acid-free. A narrative about the artwork that includes the artist’s signature is placed on the back of the artwork.

Please note: The look of the artifacts in the artworks may vary, each piece is unique.