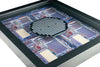

Silicon Wafer with Rockwell Microprocessor Chips - 4 inch - Aloha

ChipScapes

About this Artwork:

This artwork is based on a Rockwell microprocessor silicon wafer. This wafer is 4 inches in diameter and was made in 1986. It has 145 computer chips on it. The chips are Rockwell 5300 series microprocessors. These microprocessors were 8-bit designs with on-board RAM and ROM memory systems. The image behind the wafer is of this silicon wafer. These microprocessors would have been used to provide digital signal processing in high-end Rockwell communications equipment. Chips designers often put their initials on the chip and sometimes some other art. In this case, they put the word “ALOHA” almost in the dead center of the chip. You can see it in the chip picture with a magnifying glass. See if you can find it. An up-close image is on the back of the artwork. I was contacted by one of the chip designers, and the reason why Aloha was placed on the chip is that the designers were promised trips to Hawaii if they could meet the aggressive deadline that they were given, which they did.

About Making Computer Chips:

Computer chips start out as ordinary sand, which is silicon dioxide. However, the silicon must be made very, very pure. The first step is to melt the sand, in a furnace that reaches about 3200o F, and mix with carbon. This first purification process creates 99% pure Silicon, a common output is Silicon Carbide. The Silicon Carbide is processed in a trichlorosilane distillation method to create 99.9999% pure silicon called polycrystalline silicon. The polysilicon is broken up into chunks. These chunks are melted in a crucible at about 2500o F. A silicon crystal seed is dipped in molten silicon and slowly drawn out to create a cylinder of silicon. These silicon cylinders are some of the purest crystals on the planet. Once the silicon cylinder is grown to the desired diameter, it is sawed into wafers. These wafers are polished to achieve a very flat mirror surface. Transistors, and other microelectronic parts, are built on the polished wafer in layers in a process called etching. The wafer is then sawed into its individual chips. Each chip is mounted in an electronic package that serves to protect it and connect it to the outside world. It has been said that computer chips are the greatest value-added product in the world. We essentially take a pile of sand and change it into thousands of dollars worth of computer chips.

Framing:

The artwork is framed in an 8"x10" black shadow box frame, with glass. All framing materials are acid-free. A narrative about the artwork that includes the artist’s signature is placed on the back of the artwork.

Please note: The look of the artifacts in the artworks may vary slightly, each piece is unique.